What is an analog to digital converter (ADC)?

The real world is full of analog signals, like sound waves or light intensity, that constantly change. ADCs, or analog-to-digital converters, translate these smooth signals into digital ones that computers can understand.

Imagine dipping a cup into a flowing river to get a water sample. An ADC takes "samples" of the analog signal at specific moments. The more samples it takes per second (sampling rate), the more accurate the conversion.

Next, the ADC needs to figure out how much water is in the cup (quantization). This depends on the ADC's resolution, like the number of markings on a measuring cup. More markings (higher resolution) mean more precise measurements.

Finally, the ADC converts the sample amount into a digital code, like a number of pebbles representing the water amount. This digital code is what the computer can work with

To determine how much water is in the cup (quantization), the ADC compares the sampled voltage to a fixed reference voltage. Imagine a line marked with the reference voltage level on your measuring cup.

This reference voltage sets the maximum value the ADC can represent. By comparing the sample voltage to the reference the ADC can determine in which range it falls into (like looking at markings on the cup) and assigns a corresponding digital code to that level. The maximum resolution of the ADC expresses the minimum signal difference the ADC can resolve into different digital codes (akin to the fineness of the markings on the cup).

The accuracy of this conversion relies on a stable reference voltage. It's like having a reliable ruler to ensure your water measurements are consistent. Some ADCs use internal references, while others allow for more precise external ones for critical measurements.

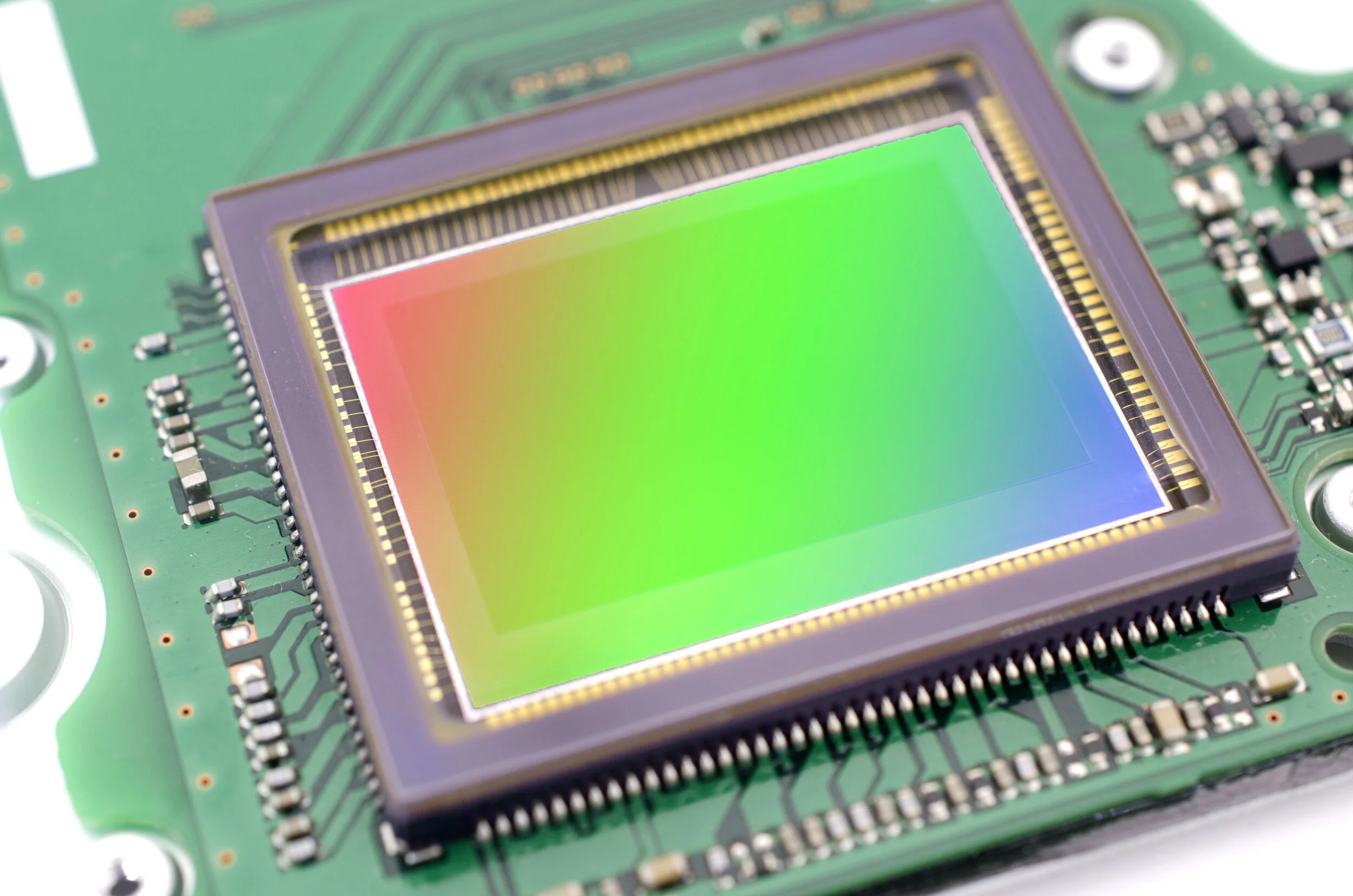

How are they used in CMOS sensors?

In a CMOS image sensor, each pixel detects light and transforms it into an electrical charge. Column-parallel ADCs come into play to translate these charges from all pixels in a single column into digital data.

Here's the twist: instead of a single ADC for the entire sensor, each column has its own ADC. This allows for much faster readout – like having multiple cups to sample the river simultaneously.

The concept remains similar. The charge from each pixel is converted to a voltage level. A shared reference voltage is used across all columns. Each column's ADC then compares the pixel voltages to this reference, assigning digital codes based on which voltage range each falls into.

This parallel processing significantly boosts the sensor's frame rate, allowing for capturing fast-moving objects or high-resolution images without compromising speed. However, designing these compact column-parallel ADCs while maintaining high accuracy and low noise is a key challenge in CMOS image sensor design.

What types of ADCs are commonly used in image sensors?

There are four main types of column-parallel ADCs used in CMOS image sensors, each with its own advantages and disadvantages:

1. Single-Slope ADC (SS ADC):

Advantages: Simple design, low power consumption, good linearity. Very compact in layout.

Disadvantages: Slower conversion speed compared to others for high resolutions, limited dynamic range in its basic form.

Single Ramp ADC

2. Successive Approximation Register ADC (SAR ADC):

Advantages: Faster conversion speed than SS ADC, good balance between power and resolution.

Disadvantages: More complex design compared to SS ADC, requires careful layout and calibration for accuracy.

Successive Approximation Register ADC (SAR ADC)

3. Cyclic ADC (CADC):

Advantages: Very high conversion speed, potentially lower power consumption than SAR ADC. Can achieve a higher dynamic range at high speed.

Disadvantages: More complex design than both SS and SAR, requires careful layout to minimize mismatch errors. Needs redundancy and error correction logic.

Cyclic ADC

4. Delta-Sigma ADC (ΔΣ ADC):

Advantages: Excellent noise performance, good for capturing high dynamic range images.

Disadvantages: Slower conversion speed compared to others, higher power consumption. Needs digital filtering to calculate the output data.

2nd order single bit ΔΣ ADC

Choosing the right type depends on the specific needs of the image sensor. Most of the consumer CMOS sensor products rely on SS ADCs, or on its variants, due to its reduced minimum size that can be well matched to the pixel pitch. For high-speed applications like sports photography, SAR or CADC might be preferred. For low-noise applications like capturing scenes with high contrast, ΔΣ ADC could be a choice. However, it may sacrifice speed.

How did the ADCs for image sensors develop in time?

The history of image sensor ADCs goes hand-in-hand with the development of CMOS image sensors themselves. Here's a breakdown:

Early Days (1960s-1970s):

Image Sensor Tech: Early image sensors, mostly MOS based, weren't as popular as CCDs.

ADC Type: Global ADCs were the norm. These used a single ADC to convert the signal from all pixels sequentially, creating a bottleneck for speed.

Rise of CMOS (1980s-1990s):

Image Sensor Tech: CMOS image sensors started gaining traction due to their potential for miniaturization and integration with processing circuitry.

ADC Type: The limitations of global ADCs became apparent. Column-parallel ADCs emerged, placing an ADC in each column to read multiple pixels simultaneously, significantly boosting frame rate.

Dominant ADC Types: Simple and low-power Single-Slope ADCs (SS ADCs) were popular choices due to their ease of implementation.

Modern Era (2000s-Present):

Image Sensor Tech: CMOS image sensors became dominant due to advancements in fabrication and integration.

ADC Type: Column-parallel ADCs continue to reign supreme. However, the choice of specific ADC type diversified based on the performance targets

How does the future look like for image sensor ADCs?

Research continues to develop even faster and more efficient column-parallel ADCs while maintaining high accuracy and low noise. As in every other ADC application field, a huge amount of “hybrid” ADC architectures has emerged, trying to combine the advantages of different architectures into a single solution.

As an example, Folding/cyclic ADCs (FI/CADCs) are a specific type of multisampling cyclic ADC used in CMOS image sensors. They combine the advantages of both folding integration and cyclic ADCs:

Folding Integration: This technique involves taking multiple samples of the pixel voltage and cleverly manipulating them (folding) to increase the effective resolution within the conversion cycle.

Cyclic Conversion: Similar to traditional CADCs, FI/CADCs perform the conversion process in multiple stages, allowing for faster overall conversion speeds.

Benefits of FI/CADCs:

Improved Noise Performance: The correlated multiple sampling technique inherent in FI/CADCs helps to reduce noise compared to standard single-sampling approaches.

High Speed Option: By reducing the number of folding cycles, the ADC can reach reasonably high conversion speeds, getting closer to a cyclic ADC in performance for lower resolution conversions

Challenges of FI/CADCs:

Design Complexity: FI/CADCs involve intricate circuitry and careful timing control, making them more challenging to design compared to simpler column-parallel ADCs.

Calibration: Precise calibration is essential to ensure all the multiple folding and cyclic samples are accurate and consistent, adding to the design complexity.

While FI/CADCs offer significant speed advantages, their design complexity and potential for mismatch errors require careful consideration when choosing an ADC for a CMOS image sensor.

Do you still use external ADCs?

While external ADCs are not typically used in modern CMOS image sensors due to the benefits of on-chip integration, there can be some advantages to using them in specific scenarios.

Advantages of using external ADCs:

Higher Precision and Resolution: External ADCs, especially high-end models, can offer superior precision and resolution compared to the often limited on-chip options. This can be crucial for scientific applications requiring extremely accurate image data.

Greater Flexibility: External ADCs provide more design flexibility. You can choose an ADC with specific features or capabilities tailored to your needs, something limited with on-chip options.

Testing and Calibration: During development and testing of a CMOS image sensor, an external ADC can be used for initial evaluation before the on-chip ADC is finalized. This allows for easier isolation and debugging of any conversion issues.

Repair and Upgrades: In some rare cases, a faulty on-chip ADC might necessitate using an external ADC as a temporary or permanent replacement. While not ideal, it can salvage a damaged sensor in specific situations.

Improved Yield: CMOS image sensor fabrication is a complex process, and any defects can render the sensor unusable. On-chip ADCs are part of this complex process, and their presence can contribute to overall yield issues. By using external ADCs, the sensor fabrication process becomes simpler, potentially leading to a higher yield of functional sensors.

Drawbacks of using external ADCs:

Increased Cost and Complexity: Adding external components like an ADC increases the overall system cost and complexity. It requires additional space, connections, and power management.

Slower Readout Speed: The data needs to travel off-chip to the external ADC, introducing additional delays compared to the direct conversion of on-chip designs. This can be a bottleneck for high-speed imaging applications.

Limited Integration: External ADCs lack the tight integration with the sensor circuitry achievable with on-chip solutions. This can limit functionalities like correlated double sampling (CDS) used for noise reduction in CMOS image sensors.

Overall, the advantages of on-chip integration for ADCs in CMOS image sensors outweigh the benefits of external options in most cases. However, for specific needs requiring the highest precision, flexibility, or for development/repair scenarios, external ADCs can still play a niche role.

PCB viewed through a microscope